In material-intensive industries such as automotive or mechanical engineering, material costs account for 40 to 70 % of the total cost of mechanical components.

The worse the design, the more material is required to fulfill the required load-bearing function. The greatest lever for minimizing material costs is therefore to reduce the amount of material used, and to do so where it is generated: In the design phase.

There is a solution for this: Design optimization!

Design optimization is the most intelligent way to exploit the weight saving potential and get even closer to the physical limit.

Design optimization can reduce net material costs by 5 to 20% for the vast majority of load-bearing structures.

Our experts answer the most important questions for both new developments and existing components:

Can I achieve the same load-bearing function with less material and thus save weight and costs?

How do I free my construction from material ballast and avoid expensive high-tech materials?

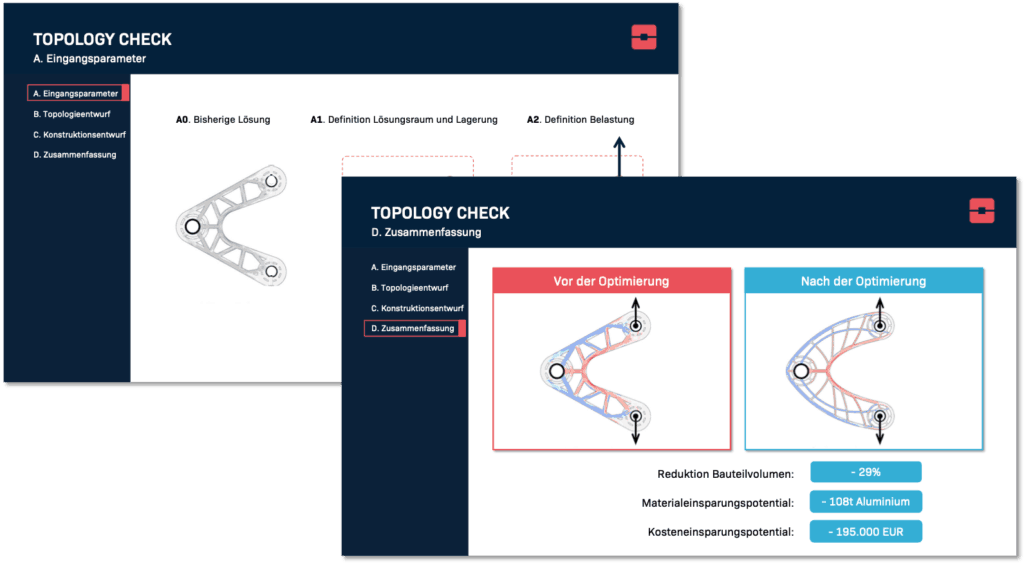

After you have registered with exaas, you get access to experts who support you with a "Topology Check" for your concept or concrete component. Either you discuss your component live and interactively via screen sharing or you provide the expert with the component drawings. He will subsequently conduct a topology optimization of the component and work out a design proposal.

And no worries, exaas ensures the confidentiality between all parties by a previously concluded agreement.

With exaas, your employees can answer difficult questions quickly and reliably with the help of external experts.

Please enter your contact details here. We will contact you afterwards to discuss about your use case.